Resources

Answers to Your Commonly Asked Questions

Stone Care

What is the difference between etching and staining?

A stain is when an ingredient such as coffee, cooking oil, wine, rust and similar sit on a natural stone long enough and absorbs into the pores of the stone causing a stain or “darkening” of the affected areas. To repair a stain, there are many types of poultice products to draw out the stain depending on the type of stain.

An etch occurs when something acidic such as lemons, vinegar, carbonated beverages, and acid-based foods and cleaners sit on a natural stone long enough that it starts to corrode or “eat” away at the surface and will give a lighter or dull appearance. If the etch is bad enough, the affected area may feel rougher (or not as smooth) as the rest of the stone.

Is there a sealer that can help prevent staining and etching?

Sealing is a common step taken on some stones as an extra precaution against staining.

Impregnating sealers are the most commonly used sealers in the industry. Sealing does not make a stone stain proof – it makes the stone more stain resistant. More Anti-Etch is a topical system that treats the stone and protects against both staining and etching.

What are the best practices for stone care?

Clean stone surfaces with a neutral (Ph balanced) cleaner, stone soap or mild dishwashing detergent and warm water. For best results, use a clean rag mop on floors and a soft cloth for other surfaces. Products containing lemon, vinegar or other acids may dull or etch calcareous stones. Scouring powders or creams may contain abrasives that could scratch certain stones.

Which materials are prone to etching and staining?

Calcareous materials such as limestone, travertine, onyx and marble are more susceptible to staining and etching, though a good quality sealer properly applied will minimize staining on these materials. Penetrating sealers will not prevent etching. Polishing powders can repair lighter etches on marbles and calcium-based stones, but to repair deeper etches on marble type materials may require the help of a stone professional.

Should dark textured stones be enhanced (honed, brushed, flannel, flamed & brushed…)?

If the material is likely to come in contact with oils (kitchens, BBQs, etc.), we highly recommend an enhancing (darkening) sealer on all dark (and even some lighter) materials for all finishes other than polished. The color of the stone becomes lighter after applying a texture to the surface and it becomes more susceptible to dark staining with oils. The oils absorb into the stone and leave darker spots. Some sealers can help prevent the oil staining, but the best way to avoid these stains is to darken the entire surface with an enhancing sealer to mask the oil stains.

Material Properties

What are the significant properties of different types of materials?

Marbles are traditionally prized for their aesthetic appeal. Some are accentuated by pronounced veining trends and bold colors. Often included in the marble family are serpentines and onyxes.

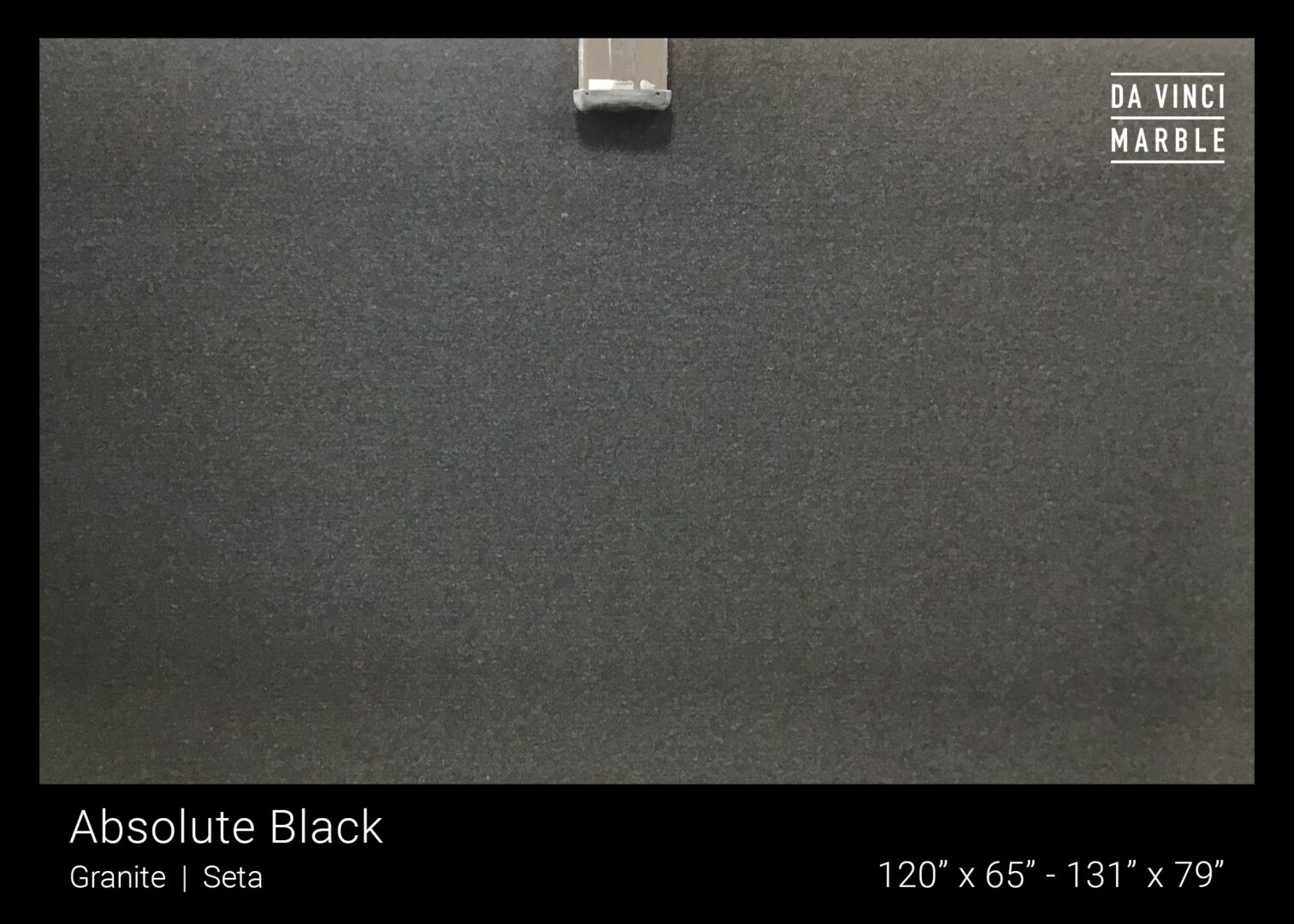

Granites typically exhibit small flecks or grains of minerals uniformly distributed throughout the stone. Some “exotic granites” will have veining patterns similar to marbles. Quartzites are generally harder and denser than granites with patterns that can resemble veining found in many marbles. Quartzite is a naturally occurring stone that is highly resistant to chemicals and scratches.

Quartzite should not be confused with manufactured quartz-based materials. Sandstones vary widely in color due to different minerals and clays found in the stone.

Sandstone is typically light gray to yellow or red. Bluestone and brownstone are well known varieties of this quartz-based stone group.

Limestone and travertines are widely used building stones with colors typically light gray, tan or buff. A distinguishing characteristic of many limestones is the presence of fossils that are frequently visible in the stone surface.

Slate is dark green, black, gray, dark red or multicolored. It is most commonly used as a flooring material and for roof tiles and is often distinguished by its distinct cleft texture.

Soapstone may come in a wide range of colors and generally feels smooth to the touch. Due to its high resistance to chemicals and because of its ability to absorb and distribute heat, it is an ideal material for countertops and surrounds for fireplaces and wood stoves.

Above descriptions are provided courtesy of the Natural Stone Institute.

Where can I get more information on properties of different stone types?

Here are some useful links from a trusted resource.

https://flexiblelearning.auckland.ac.nz/rocks_minerals/rocks/granite.html https://flexiblelearning.auckland.ac.nz/rocks_minerals/rocks/quartzite.html https://flexiblelearning.auckland.ac.nz/rocks_minerals/rocks/marble.html https://flexiblelearning.auckland.ac.nz/rocks_minerals/rocks/limestone.html https://flexiblelearning.auckland.ac.nz/rocks_minerals/rocks/sandstone.html

Finish Types

What finish options are available for your materials?

We offer a large variety of finishes on our materials — we currently have materials in stock with polished, honed, leathered, flamed, brushed, flamed and brushed, seta and flannel finishes. However, not all finishes are available for all materials so please check our website or contact us to find out what we can offer. Additionally, we can and often do accommodate requests as special, custom orders.

Material Applications

Is marble an appropriate material for kitchens?

At Da Vinci, we believe marble is a great material for a kitchen.

Homeowners should evaluate how appropriate marble is for their lifestyle, however. Acidic foods or liquids can cause staining as can strong dies present in some foods. A sealer can prevent a large percentage of staining and a good poultice can be used to remove a stubborn stain if necessary.

A bigger issue to be taken into account is etching — most sealers cannot prevent etching. Etching takes place when acids eat away at the polish on marble causing it to patina over time. White marble is can be a good solution because the etching is not highly visible, especially with a honed finish. Colored marbles will turn white where they etch, and the contrast will probably not be acceptable for most homeowners.

If you find the potential for etching in white marble troubling, or if you would like to use colored marble in your kitchen, we recommend you consider More Anti-Etch topical sealer. This sealer, fairly new to the market, can prevent etching and staining on any marble counter.

https://www.moresurfacecare.com/pages/more-antietch-anti-etch

Are man-made quartz slabs or porcelain slabs appropriate for the outdoors?

Porcelain slabs are great for outdoor use because they will not etch, scratch, or stain.

Quartz slabs cannot be used in outdoor settings with direct sunlight because they contain resins, which can break down and discolor in sunlight.

What are book-matched slabs?

Slabs are cut sequentially from a block, like a loaf of bread. Slabs are “book-matched” when the factory polishes adjacent faces. Two adjacent book-matched slabs will be mirror images of each other; this is important because the veins line up when book-matched slabs are placed next to each other. The veins continue across the seam, which is especially important for a large spaces, such as a large island or a long counter in a kitchen.

Is it ok to use marble, limestone, onyx, and travertine in a bathroom?

There is no single answer to this question. As is true with marble in kitchens, you will find differing opinions. From our point of view, all our materials are great in a bathroom application though it is possible for all of these materials to stain or lose their shine over time.

Fabrication

Does Da Vinci fabricate and install the material it sells?

Da Vinci does not fabricate or install material, nor do we make recommendations. Having said this, we are happy to share a list of fabricators and installers in the area.